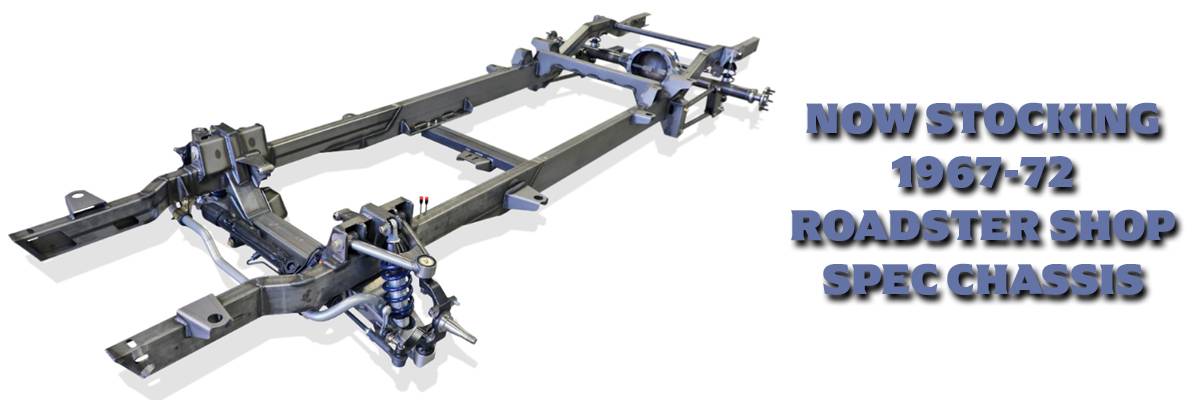

OVERVIEW

SPEC is an engineering focused approach using the latest in manufacturing technology to build the lightest, strongest, and easiest to install complete chassis system. These technologies have been used to streamline procedures resulting in lower cost and shorter lead times. The SPEC IFS is engineered to deliver outstanding performance wrapped up in user friendly package. A completely new proprietary suspension geometry has been designed to provide the best balance of ride quality and performance in its class.

The Benefits:

- No kinks, bends or stressed areas that are prone to flex like mandrel bent tubing

- Ability to contour to stock floors for no floor modifications on most applications

- Stronger, lighter, and more precise.

- CNC located factory mounts built into the frame for easy, vehicle specific installation

- Frame rail designs to accommodate mini-tubs and up to 12″ wide wheels

- No need to work with a weak, twisted 30-50 year old frame

- No need to cut, c-notch, and step your original frame and worry about keeping everything square

STANDARD FEATURES

- RS exclusive “Laser Rails” precision CNC laser cut and contoured

- Crossmembers and chassis bracing to allowing for 3″ exhaust

- Engine mounts for SBC, BBC, or optional LS & LT

- Adjustable, drop out trans mount

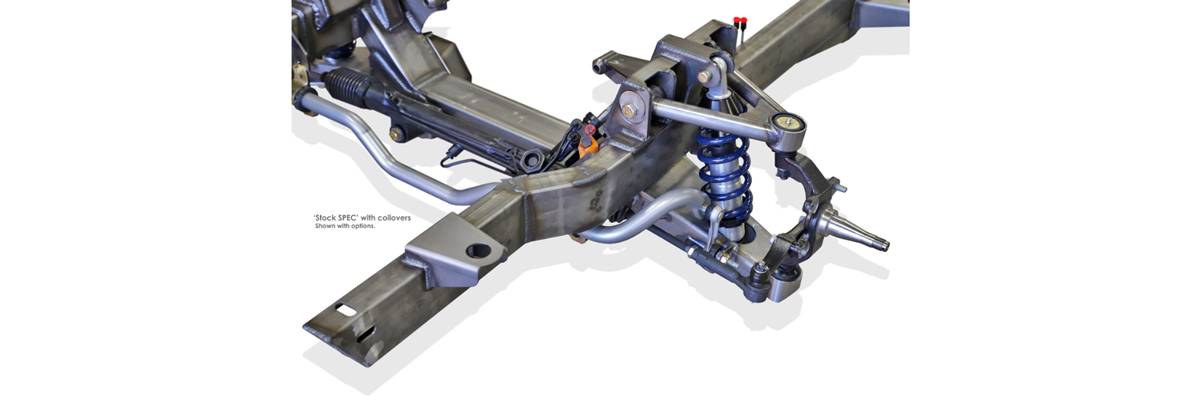

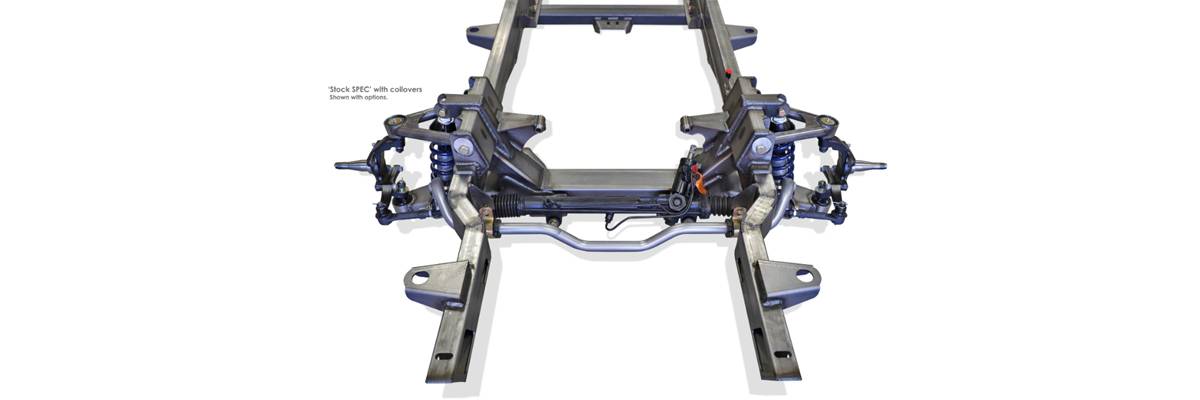

SPEC IFS

- Single adjustable billet coilovers

- Power rack & pinion steering

- Easy to adjust upper a-arm eccentric mounts for fast and accurate alignments

- Wilwood Pro Spindle

- No floor modifications required for chassis installation

- Trans tunnel mods may be necessary for larger T-56 and 4L80 transmissions

- Utilizes factory body, bumper, and core support mounts for a true bolt-on installation

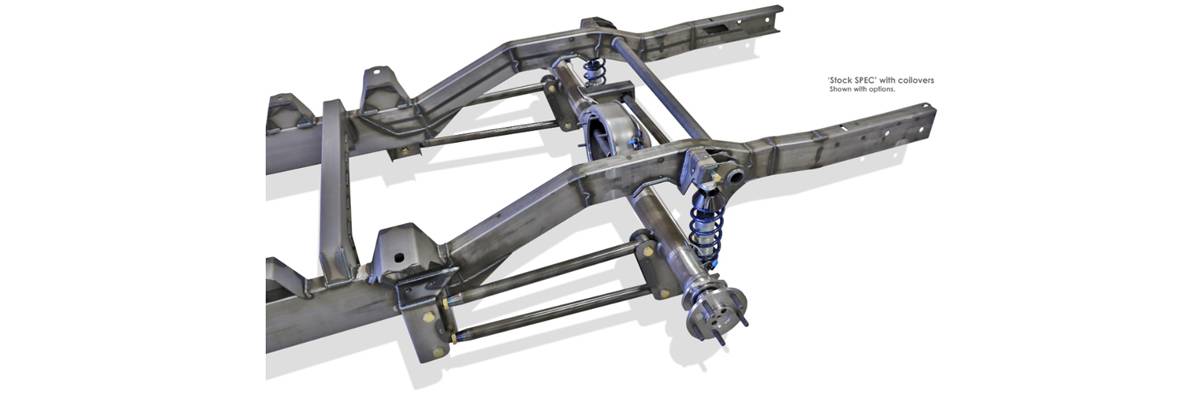

- Parallel 4-Bar rear suspension

- Single adjustable billet coilovers

- Ford 9″ housing with 31 spline axles

- Rear frame rails will accommodate up to a 345 tire (when mini-tubbed)